Case Study: High-Capacity Powerlock Distribution Panel for Major Events

02/02/2026

KES Power & Light were approached to design and manufacture a heavy-duty Powerlock distribution panel capable of handling substantial incoming capacity and delivering reliable high-current output for a major events client. The brief focused on performance, durability and ease of deployment across large and demanding sites.

The enclosure was built from 2 mm Zintec steel and mounted within a fully welded 50 mm × 3 mm galvanised crash frame. With lifting hooks, forklift pockets and a total weight of around 500 kg, the unit was engineered for repeated transport and handling in challenging conditions. The mechanical design ensured long-term resilience while allowing easy access for installation and service work.

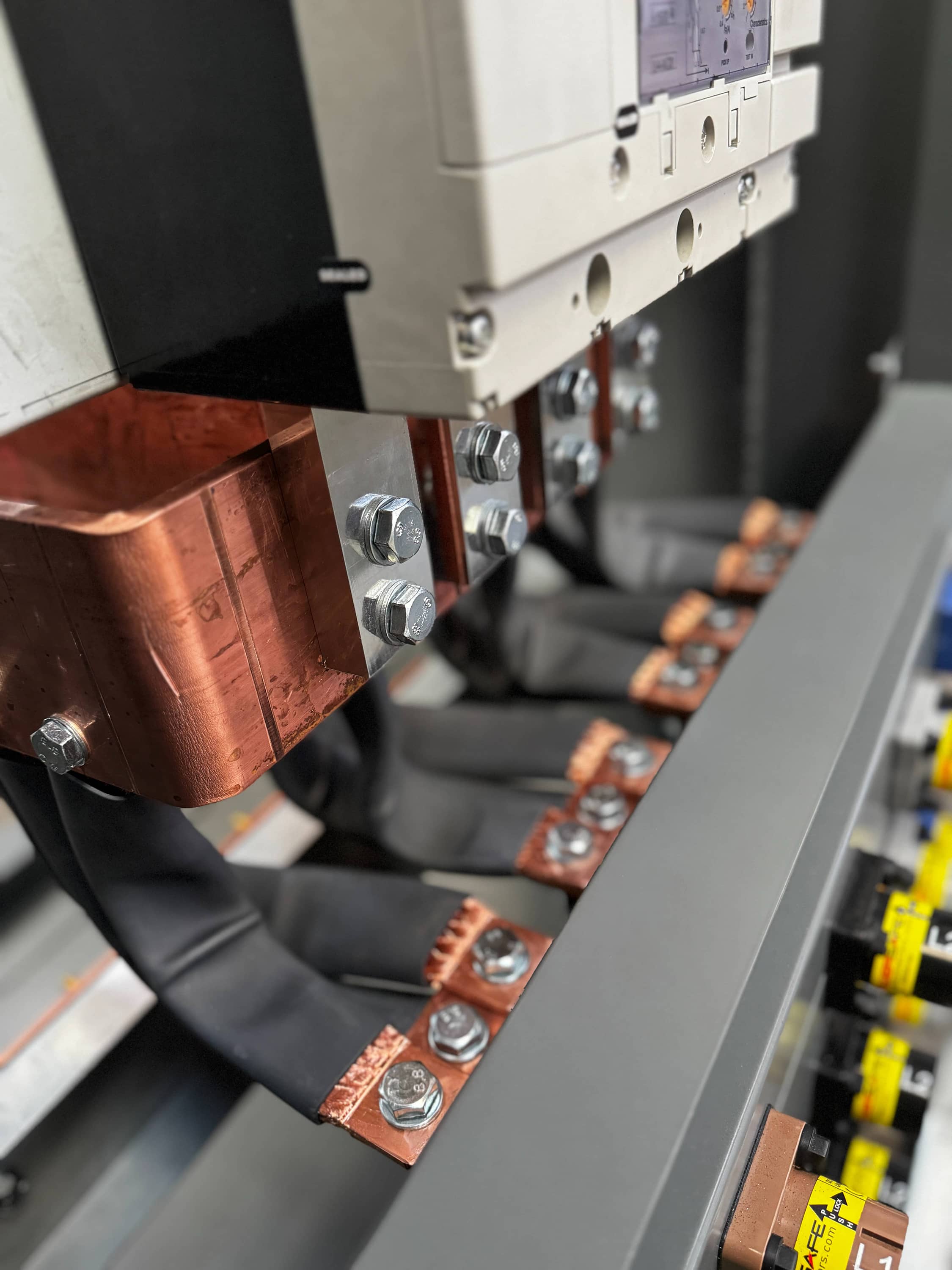

Electrically, the panel offered three incoming supplies, each comprising two full sets of 800 A panel drain Powerlocks protected by a single 800 A four-pole MCCB. Lugged cable terminations were made via solid copper bar, providing strong, low-resistance connection points and simplifying installation for high-current feeds. This triple-incoming arrangement gave the client excellent flexibility for multi-generator setups, redundancy or load-sharing configurations often required on large-scale event infrastructure.

For outgoing distribution, the panel delivered four sets of 500 A panel source Powerlocks fed from a central 1600 A four-pole MCCB. Flexibar copper was selected for the outgoing Powerlock connections, helping to maintain compact routing while offering proven vibration resistance during transport and use. The main copper busbar was manufactured from 100 mm × 10 mm copper to ensure reliable performance under continuous load. Additional copper brackets—50 mm × 6 mm and 60 mm × 10 mm—provided strong and efficient links between the breakers and the outgoing terminals.

As with all large-format builds at KES, the panel was designed by the in-house CAD team and manufactured at the Southampton facility using CNC fabrication and precision-machined copperwork. Thermal spacing, mechanical bracing and operator safety were key considerations throughout the design process.

The finished solution gave the client a robust, high-capacity distribution hub capable of supporting large event builds with confidence. Its combination of high-current protection, multiple supply options and a durable crash-frame enclosure makes it well suited for regular deployment across major shows, festivals and temporary power networks.